Injection Molded Light Shaping Diffusers®

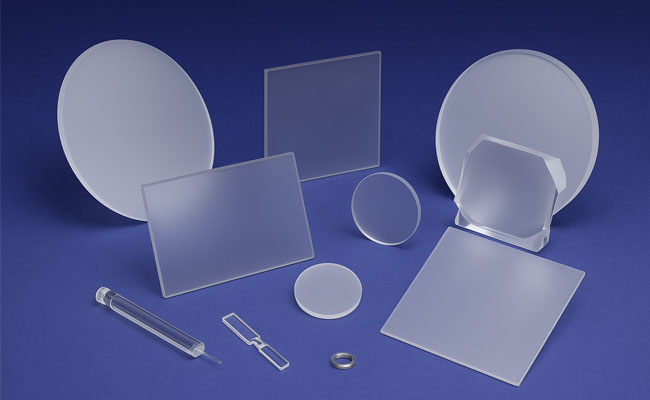

For high-volume lighting applications, Luminit offers cost-effective, rigid injection molded Light Shaping Diffusers® that combine precision optics with scalable manufacturing. These diffusers use a proprietary shim-insert molding process to embed our patented microstructures directly into rigid lenses up to 6 inches (150mm) in diameter.

Designed for production runs of 10,000 units or more per year, injection molded diffusers reduce per-unit costs while delivering consistent optical performance. These custom lenses are ideal for a wide range of lighting formats, including recessed downlights, spotlights, PAR (Parabolic Aluminized Reflector), and MR (Multifaceted Reflector) lamp designs.

By integrating Luminit’s Light Shaping Diffuser® technology directly into the exit window of the lamp or fixture, customers gain a rigid optical element that delivers:

- High transmission efficiency (85–92%)

- Smooth, frosted finishes

- Precise, uniform beam control

Lenses can also be engineered with mechanical tabs or clips molded into the lens body for fast, snap-in-place installation, further reducing labor and assembly time.

Key Benefits of Injection Molded Light Shaping Diffusers

Injection molded Light Shaping Diffusers® are built for performance, precision, and production scalability, making them a go-to solution for OEMs and lighting manufacturers:

- Very high transmission efficiency (85%–92%)

- Supports Energy Star compliance for lighting products

- Available in symmetrical and asymmetrical beam angles

- Optional integrated mechanical clips for snap-together assembly

- Can be produced with non-yellowing materials for outdoor use

- Compatible with a wide range of lamp and fixture formats

Common Applications

Ideal for applications where durability, beam control, and cost-efficiency are key, Luminit’s injection molded diffusers serve a variety of lighting markets:

- Recessed downlights

- Spotlights and flashlights

- PAR and MR lamps

- Architectural and commercial lighting

- Outdoor and weather-resistant lighting systems

Transform Your Lighting with

Injection Molded Diffusers

If you’re producing lighting systems at scale, Luminit’s injection molded Light Shaping Diffusers® can help you achieve optical precision at a competitive cost. Our engineering team can assist with angle selection, mechanical integration, and custom lens designs tailored to your fixture or form factor. Contact our sales team to discuss your requirements or request a sample to see the benefits of injection molded Light Shaping Diffusers firsthand.