Better Optics, Better View: How Luminit Is Advancing Near-to-Eye and Head Up Displays

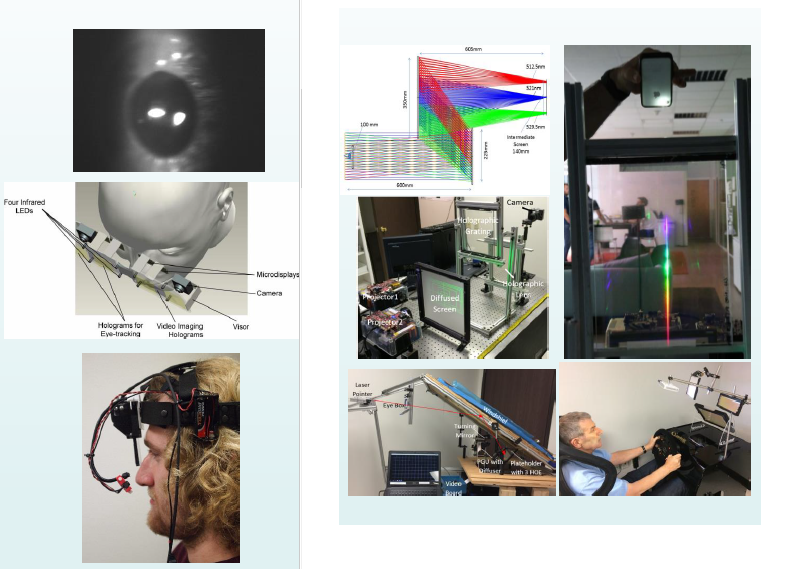

Once labeled as “hype” only a few years ago, Augmented Reality glasses and vehicle Head-up Displays (HUDs) are beginning to penetrate the mainstream, and countless opportunities lie ahead. Luminit has been on the forefront of this promising technology since 2004, beginning with an SBIR grant to develop a Head-mounted Display (HMD) for the US Army using Holographic Optical Element (HOE) technology. Since then, Luminit has been awarded multiple patents related to design and manufacturing of HOEs, and our technologies are making it possible to deliver compact and efficient Head-up Displays for vehicle windshields as well as smaller and lighter Near-to-Eye Displays.

From HOE to Transparent Holographic Components

Luminit combined its holography expertise with its thin-film mass production capabilities to create Transparent Holographic Components (THCs). THCs are Holographic Optical Elements recorded on photopolymer film that can be applied to glass or rigid polymer surfaces. The technology offers distinct advantages over conventional bulk optics, because the transparent volumetric holographic photopolymer mimics the properties of these optics but in a thinner and lighter format. While the idea of using HOEs in see-through applications to replace a traditional lens or grating is not new, Luminit has developed a manufacturing process that is scalable to address consumer-type volumes.

More Volume, Less Space

A key benefit of Holographic Optical Elements is its size and weight. Replacing convex lenses, mirrors, prisms and gratings with a thin film optic leaves room to design near-to-eye displays like smart glasses that are light, stylish and integrate seamlessly with the wearer’s lifestyle. Luminit THCs are less than 30 microns thick; however, the holograms have Bragg properties that are wavelength and angle selective with very low scattering, low haze and high transparency. Total efficiencies can be up to 90 percent.

Colorful and Scalable on a Single Layer

Creating a full color (RGB) hologram is a complex process, which is why existing HUDs are often monochromatic (red or green) or 2-color. Usually, to produce an RGB image, HOEs are recorded on three separate layers of photopolymer film. The disadvantage with three layers is optical efficiency—more layers, less transmission. Three layers also present alignment or “misalignment” challenges that can reduce the image quality. Luminit’s research and development with Tier 1 auto suppliers gave our holography team the opportunity to experiment with different recording techniques. Most recently, Luminit successfully developed a single layer RGB HUD which was showcased at this year’s Display Week in San Jose. Luminit Transparent Holographic Component HOE technology records all three wavelengths on a single film, thus minimizing the risk of misalignment and simplifying the integration. Luminit Transparent Holographic Components are also scalable, meaning the holograms can be produced in quantities from 5 to 50,000 per month.

High Volume, Low Cost

Although HOE offer obvious advantages over conventional optics, robust adoption has been slow due to the lack of mass production capabilities. Luminit Transparent Holographic Components optical mastering and replication support Augmented Reality for near to eye and head up displays with a roll-to-roll platform that replicates diffractive Holographic Optical Elements at high volumes and low cost.

Augmented Reality has countless applications across a wide range of industries. However, the ultimate success of Head Up and Near-to-Eye Displays depends on companies like Luminit who can deliver compact, colorful holographic images to what is sure to be the next machine-to-human interface.

To learn more about Luminit Transparent Optical Components, contact sales@luminitco.com